PT 15 Fence Framework

Count on US Premier Tube Mills to supply the strong, corrosion-resistant fence framework you need for light commercial and select residential projects. PT 15 is a reliable choice for applications like parks, playgrounds, parking areas, and larger gates. Manufactured in the USA with our advanced coating process and high strength steel, PT 15 offers lasting durability and dependable performance.

Product Overview

PT 15 from US Premier Tube Mills is designed for light commercial and select residential fencing applications that demand added strength and corrosion resistance. Ideal for parks, playground enclosures, parking facilities, and large residential gates, PT 15 offers high performance in a lightweight form.

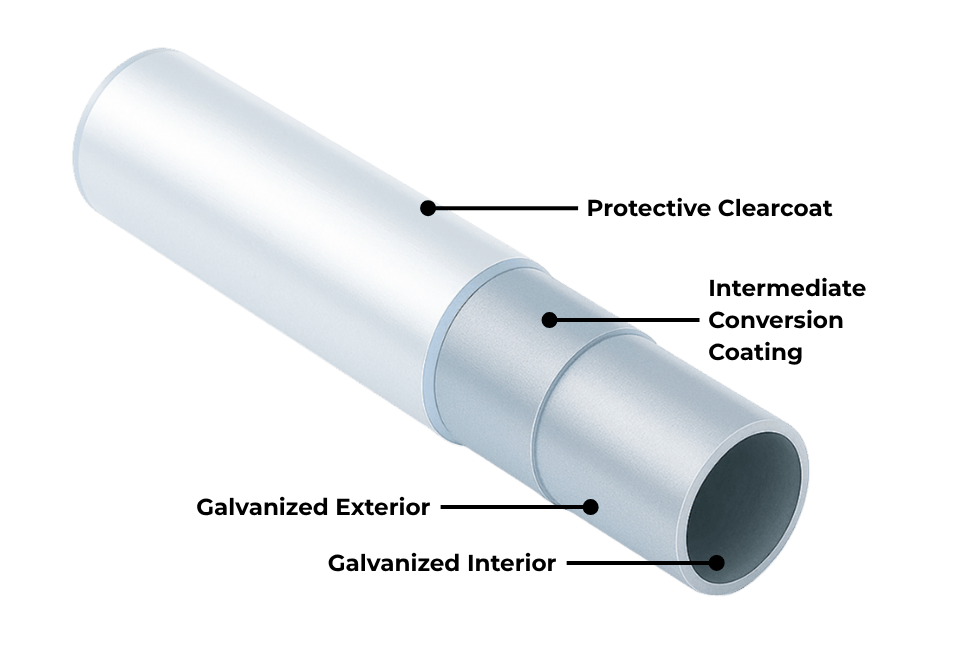

Manufactured with high-yield steel at 50,000 PSI minimum yield strength, PT 15 is 40 percent stronger and 35 percent lighter than traditional hot-dip galvanized pipe. It is protected inside and out with our advanced inline triple-layer coating system. This includes a hot-dipped zinc layer, a conversion coating, and a clear exterior top coat, with the interior fully zinc-coated before forming—ensuring long-term corrosion resistance in harsh environments.

PT 15

Light Commercial and Residential

vs. Hot Dip Galvanized Pipe Comparison Chart

| Posts | Outside Dimensions (in.) |

Pipe Wall Thickness (in.) |

Weight (lbs./ft.) |

Section Modulus (inches³) |

Yield Strength (psi) |

Bending Moment (lbs. in.) |

Bending Strength (lbs.) 4' Cantilever |

Bending Strength (lbs.) 6' Cantilever |

Bundle Counts (lbs.) |

|

|---|---|---|---|---|---|---|---|---|---|---|

| 1-⅝" O.D. | PT 15 | 1.660 | 0.072 | 1.22 | 0.1367 | 50,000 | 6,835 | 142 | 95 | 61 |

| HDG | 1.660 | 0.110 | 1.82 | 0.1948 | 25,000 | 4,870 | 101 | 68 | ||

| 1-⅞" O.D. | PT 15 | 1.900 | 0.072 | 1.41 | 0.1821 | 50,000 | 9,104 | 190 | 126 | 61 |

| HDG | 1.900 | 0.110 | 2.10 | 0.2618 | 25,000 | 6,544 | 136 | 91 | ||

| 2-⅜" O.D. | PT 15 | 2.375 | 0.072 | 1.77 | 0.2911 | 50,000 | 14,556 | 303 | 202 | 37 |

| HDG | 2.375 | 0.110 | 2.66 | 0.4237 | 25,000 | 10,592 | 221 | 147 | ||

| Top Rail - 10' Free Supported | ||||||||||

| 1-⅜" O.D. | PT 15 | 1.315 | 0.072 | 0.96 | 0.0829 | 50,000 | 4,143 | 138 | 91 | |

| HDG | 1.315 | 0.110 | 1.42 | 0.1159 | 25,000 | 2,898 | 97 | |||

| 1-⅝" O.D. | PT 15 | 1.660 | 0.072 | 1.22 | 0.1367 | 50,000 | 6,835 | 228 | 61 | |

| HDG | 1.660 | 0.110 | 1.82 | 0.1948 | 25,000 | 4,870 | 152 | |||

For additional sizes and availability, please contact our team!

Our Manufacturing Process

All of our pipe products are manufactured using a state-of-the-art process that ensures each length is precision-formed for strength, consistency, and long-term reliability. With our signature triple-layer corrosion protection, consisting of a zinc-coating inside and out with a clear topcoat. They’re built to resist rust, corrosion, and environmental wear, making them ideal for outdoor and high-traffic applications.

Sustainable By Design

By using partially recycled, 100% domestically sourced steel, our products can contribute valuable credits toward your LEED-certified projects. It’s a responsible choice that aligns with modern standards without compromising strength or performance.

Technical Specifications & Compliance

Superior Corrosion Resistance

Our triple-layer inline coating process guarantees the highest degree of corrosion resistance available. This includes an initial hot dip steel, an intermediate conversion coat, and a clear topcoat.

Proudly Made in the USa

All US Premier products are proudly manufactured in the USA using 100% domestic steel, fully meeting Buy America(n) compliance standards.

Backed With Confidence

At US Premier Tube Mills, quality is our promise. Our galvanized tube and pipe products are backed by a 3-year limited warranty, and our Color Coat line carries a 15-year limited warranty against fading, flaking, cracking, or crazing. This ensures long-term durability under proper use. We stand by our craftsmanship so you can build with confidence.

Color Coated Tubing Built to last

All US Premier Tube products are available in black, green, or brown, finished with our durable 15-year Color Coat system. It is engineered not to fade, crack, flake, or craze. Custom colors are also available upon request.